Construction Zones Made Safer: RTLITE's Work Zone Materials at Work

Understanding Work Zone Safety

A work zone is an area designated for activities like highway construction, maintenance, or urban development, requiring alterations in regular traffic patterns. These zones often include barriers, cones, and warning signs to protect both workers and the public. Work zones can vary from small, temporary setups to large-scale, long-term projects. Their primary goal is to establish a controlled environment that minimizes hazards while essential tasks are carried out effectively.

The importance of work zone safety cannot be overstated, as it plays a vital role in safeguarding workers, motorists, and pedestrians. Proper safety protocols are essential for efficient traffic management and for mitigating risks associated with high-speed traffic and heavy machinery. By ensuring work zone safety, we can prevent accidents, protect lives, and maintain smooth traffic flow. The success of these zones hinges on strict adherence to safety measures, including proper signage and speed regulation.

Recent statistics underline the pressing need for effective work zone safety measures. According to the Federal Highway Administration, work zone incidents resulted in 891 fatalities and over 37,700 injuries in 2022 alone. Most fatalities involve drivers or passengers, but pedestrians and bicyclists are also at risk. Notably, incidents involving large commercial motor vehicles saw a significant increase, underscoring the urgency for robust safety protocols. These statistics highlight the necessity of focusing on and enhancing work zone safety initiatives to protect all road users.

Key Components of Work Zone Safety

Work Zone Signs and Their Impact:

Work zone signs are pivotal in conveying crucial information to drivers, thereby significantly reducing accidents. These signs include alerts such as "Work Zone Begins," "Road Work Ahead," and "Construction Area," marking the start of a work zone and helping prepare drivers for upcoming changes in traffic patterns. Research shows that clear signage leads to improved driver behavior, reducing sudden stops and lane changes by 40%.

Traffic Control Measures in Work Zones:

Effective traffic control measures are essential for ensuring safety within work zones. These include cones, barriers, and diversion signs strategically placed to manage vehicle flow and delineate safe pathways. Such measures help maintain order, preventing confusion and potential collisions. Studies indicate that properly implemented traffic control can reduce work zone accidents by up to 15%.

Personal Protective Equipment (PPE) for Workers:

Personal protective equipment (PPE) is critical in safeguarding workers within work zones. Essential PPE includes helmets, reflective vests, and safety eyewear, providing protection against head injuries and ensuring visibility. Compliance with regulations from agencies like OSHA is mandatory to ensure worker safety. OSHA mandates appropriate PPE usage, contributing to a 30% reduction in worker injuries in compliant work zones.

Common Hazards in Construction Work Zones

Construction work zones, often bustling with heavy machinery like cranes and excavators, inherently possess significant risks. These high-powered machines can lead to accidents if not properly managed. Common accidents include machinery tipping over or backing incidents. Preventive strategies include implementing strict safety protocols, conducting routine equipment maintenance, and providing regular training sessions for operators to ensure they remain vigilant and competent in handling machinery.

Environmental conditions also play a critical role in work zone safety. Adverse weather, such as rain or snow, can create hazardous working conditions, while uneven terrain may pose balance and movement challenges for both workers and machinery. To mitigate these environmental risks, project managers should incorporate weather forecasts into planning and employ terrain analysis tools. Additionally, equipment designed for better traction and the use of temporary surfaces or supports can help stabilize the working environment.

Human factors are often a significant source of accidents in construction work zones. Errors stemming from fatigue, distraction, or insufficiently trained personnel introduce unnecessary risk. Managing these hazards requires enforcing strict work-hour regulations to combat fatigue, minimizing distractions in high-risk areas, and ensuring comprehensive training programs are in place. These efforts should focus on equipping workers with both the knowledge and practical experience needed to operate safely within a dynamic work zone environment.

How RTLITE's Work Zone Materials Enhance Safety

RTLITE offers a range of products designed to improve safety in work zones, particularly during nighttime operations.

1. 5cm*50m RTLITE Metallized Super Adhesive ECE 104R Safety Warning Sticker Reflective Tape for Heavy Truck: This tape provides excellent reflective properties, ensuring heavy trucks are visible from a distance. Its ECE 104R compliance guarantees that it meets European standards for vehicle conspicuity. The tape’s weather resistance further enhances its durability across different conditions.

2. Red White Reflective Tail Lift Flags Warning Marking For Truck Honeycomb Reflective Flags: These flags are crucial for enhancing truck visibility, thereby reducing accidents. Their construction using honeycomb reflective technology ensures they can withstand adverse weather conditions while maintaining high visibility.

3. 135MMX565MM Heavy Truck Vehicle Rear Safety Warning Chevron Adhesive Reflective Sticker: This chevron sticker alerts drivers to the presence of large vehicles, especially in low-light conditions. Its micro-prismatic construction improves durability and ensures sustained reflectivity over time.

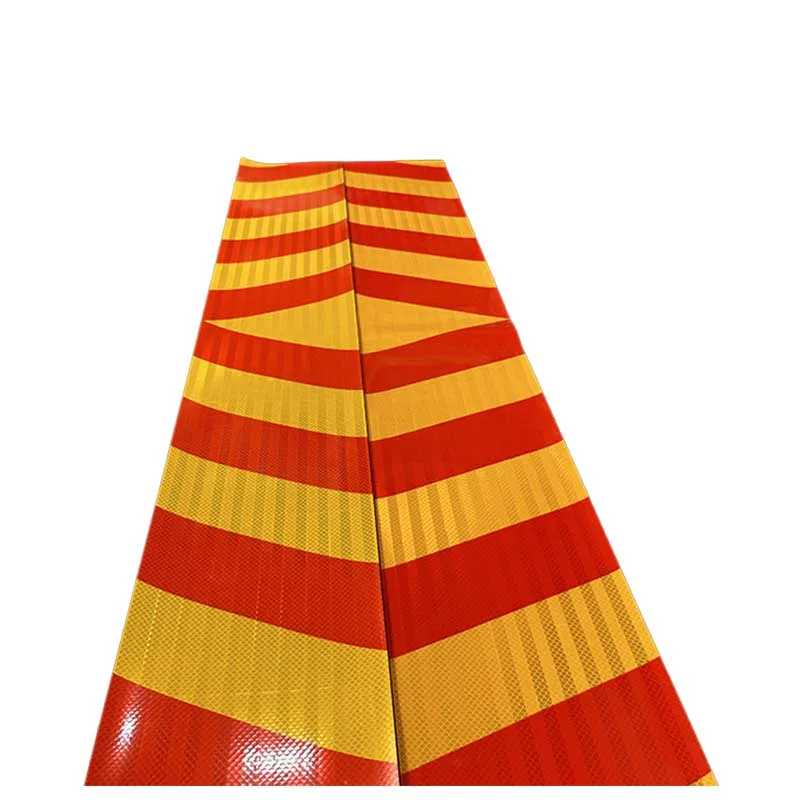

4. 3 Years PET Truck Safety Red Yellow Heavy Vehicle Rear Reflective Marking Plate Chevron Reflective Sticker: This marking plate is designed for lasting performance, featuring materials that comply with regulatory standards. Its bright chevron pattern increases visibility to prevent collisions.

5. 1.24m*50m Honeycomb Self Adhesive Reflective Vinyl PVC Reflecting Sheeting Eco Solvent Printing Reflective Film: Suitable for multiple applications, this reflective film offers environmental benefits through its eco-solvent printing compatibility. Its durability and flexible application make it ideal for temporary traffic signs and work zone markers.

Effective Safety Strategies for Work Zones

Implementing effective safety strategies in work zones is crucial to mitigate hazards and ensure the safety of workers and motorists. Regular safety training and awareness programs are essential for equipping workers with the knowledge and skills necessary to navigate the challenges of work zones. These programs empower employees to recognize and handle dangerous situations, ultimately reducing workplace accidents. By staying informed on best practices and up-to-date safety measures, workers can maintain a high level of awareness and responsiveness in varying scenarios.

Additionally, strict enforcement of safety regulations is vital for maintaining order and reducing risk in work zones. Agencies like the Occupational Safety and Health Administration (OSHA) have established guidelines that must be rigorously followed to prevent accidents and injuries. Non-compliance with these regulations can lead to severe penalties, reinforcing the importance of adherence. Regular audits and inspections ensure that safety protocols are consistently upheld, contributing to a safer work environment.

Lastly, identifying and promoting best practices for drivers in work zones significantly enhances safety. Drivers should be keenly aware of speed regulations, maintaining a reduced speed according to posted limits to ensure both their own safety and that of others. Additionally, paying close attention to signage and adopting a cautious approach when navigating through work zones can prevent accidents. Encouraging such behaviors among drivers not only safeguards the workers but also minimizes traffic disruptions, thereby improving overall road safety.

Future Innovations in Work Zone Safety

The future of work zone safety is being reshaped by technological advancements that are set to significantly minimize risks. Notable among these are the use of drones and smart traffic management systems. Drones can provide real-time aerial views of construction sites, allowing project managers to swiftly identify and address potential hazards. Meanwhile, smart traffic systems can help regulate traffic flow with greater precision, using real-time data to adapt to changing conditions and reduce congestion, ultimately enhancing safety for both workers and drivers.

Emerging safety materials are also playing a crucial role in improving work zone conditions. New materials are being developed to enhance visibility and increase the durability of barriers and signage. These materials include reflective technologies that increase night visibility and weather-resistant compounds that ensure longevity under harsh conditions. By using these innovative materials, work zones can become more secure and reduce the likelihood of accidents.

Automation is another key component driving safety improvements in work zones. Automated machinery and vehicles are reducing the reliance on human intervention, minimizing the risk of human errors that often lead to accidents. Automation allows for precision and consistency in tasks such as excavation and material handling, which are traditionally labor-intensive. Consequently, integrating automation into work zones can significantly improve safety outcomes by reducing accident rates and enhancing overall efficiency.

EN

EN

ONLINE

ONLINE