Enhancing Road Safety with Reflective Materials

Understanding Reflective Materials in Road Safety

Reflective materials are crucial for road safety due to their ability to enhance visibility. These materials are primarily composed of high-performance microbeads or prismatic elements, which are specifically designed to reflect light effectively. The microbeads are tiny glass spheres, while the prismatic elements are structured micro-prisms. Both of these components are integral in bouncing back light towards its source, a characteristic known as retroreflectivity, making these materials invaluable in low-light conditions.

The properties that make reflective materials ideal for road safety include their retroreflectivity and durability. Retroreflectivity allows these materials to reflect light, such as vehicle headlights, back towards the driver, significantly improving visibility at night or in poorly lit areas. Furthermore, the longevity of these materials under various environmental conditions ensures consistent performance over time. By effectively employing reflective solutions, the risks of road accidents can be considerably reduced, offering a safer travel environment for all road users.

Benefits of Enhancing Road Safety with Reflective Materials

Reflective materials significantly improve road safety by increasing visibility during night-time and low-light conditions. These materials rely on retroreflectivity, a property that allows them to bounce light back to its source, such as a vehicle's headlights. This capability is crucial in reducing accidents, as studies indicate that the risk of night-time collisions is significantly higher. For instance, according to the National Highway Traffic Safety Administration (NHTSA), approximately 50% of traffic fatalities occur at night despite lower traffic volumes, demonstrating the importance of enhanced visibility.

Another key advantage of reflective materials is their durability and weather resistance. These materials are designed to withstand harsh weather conditions, including rain, snow, and UV exposure. As a result, they maintain their effectiveness over longer periods, making them a cost-effective solution for road safety. The use of durable materials such as acrylic or polycarbonate ensures that signs and road markings remain highly visible and effective regardless of environmental conditions. This resilience is crucial for maintaining safety standards, especially in regions with extreme weather variability, ensuring that reflective materials perform optimally throughout the year.

Types of Reflective Materials

Reflective materials are crucial in enhancing visibility and safety across various applications, with two main types being glass bead and micro-prismatic reflective materials.

1. Glass Bead Reflective Material: This traditional reflective material is made with tiny glass beads enclosed within a transparent coating. When light hits the surface, these beads refract the light and then reflect it back towards its source, improving visibility. One of the significant advantages of glass bead reflective material is its cost-effectiveness, as it provides adequate reflectivity at wide angles. However, its performance may degrade over time due to wear and tear, as dirt and age can affect the beads' reflective efficacy.

2. Micro-Prismatic Reflective Material: A more modern approach to reflective technology, micro-prismatic materials consist of small prisms arranged in a uniform pattern on a flexible surface. These materials offer significantly higher brightness and visibility compared to glass bead materials. They reflect light more efficiently, covering longer distances and broader angles, making them ideal for modern road safety systems. Additionally, micro-prismatic materials are known for their durability and maintenance of reflective performance, even after prolonged exposure to harsh environmental conditions. Their superior performance makes them particularly suitable for high-visibility applications, such as on vehicle surfaces where long-term effectiveness is vital.

Both glass bead and micro-prismatic reflective materials contribute uniquely to safety and visibility, each fitting different needs based on cost, durability, and effectiveness.

Best Practices for Implementing Reflective Materials

Successfully installing reflective materials requires attention to detail and adherence to best practices. Here are some structured guidelines to ensure optimal installation:

1. Surface Preparation: Begin by thoroughly cleaning and drying the surface where the reflective tape or sticker will be applied. This ensures maximum adhesion and longevity.

2. Alignment Strategies: Use a straight edge or level to align the reflective material properly. This ensures that the material isn't skewed and covers the desired area effectively.

3. Recommended Tools: Employ tools such as squeegees or rollers to apply even pressure across the reflective tape, minimizing air bubbles and wrinkles.

In addition to installation guidelines, maintaining reflective materials is crucial for their effectiveness over time. Proper maintenance practices include:

- Inspection Schedules: Regularly inspect the reflective materials for wear, such as fading or peeling. This should ideally be done every few months to ensure they maintain high visibility.

- Cleaning Procedures: Use a soft cloth and mild detergent to clean the surface of the reflective material. Avoid abrasive cleaners as they can scratch the reflective coating, leading to reduced reflectivity.

Adhering to these installation and maintenance best practices will help ensure the longevity and performance of reflective materials, such as reflector tapes or glow-in-the-dark stickers, thereby enhancing safety and visibility in various contexts.

Product Highlights: Enhance Road Safety with These Reflective Materials

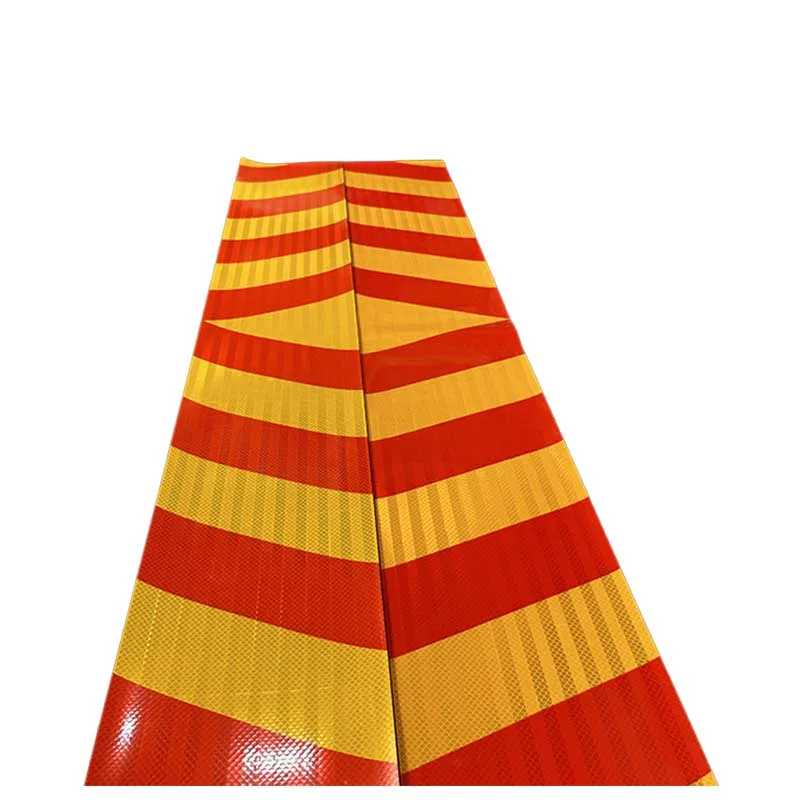

Enhance your vehicle's safety with the Red & Yellow 5 Years Warranty Truck Safety Reflective Sticker. This product is designed with vibrant red and yellow colors that significantly enhance visibility on the road. The reflective material uses micro-prismatic technology for superior reflective performance, ensuring that heavy vehicles are easily noticeable even in low-light conditions. Its robust waterproof and weather-resistant qualities ensure longevity and consistent performance.

The High Intensity Rectangle Style Yellow Red Reflective Sheeting Sticker offers a sophisticated design that boosts reflectivity for better road presence. This rectangle micro-prismatic reflective film has been crafted to meet the stringent requirements for rear marker boards on heavy vehicles. It offers exceptional visibility through its red and yellow hues. Its durable design features waterproof and weather-resistant properties, making it an ideal choice for consistent safety performance.

For those seeking robust solutions, the 3 Years PET Truck Safety Red Yellow Heavy Vehicle Rear Reflective Marking Plate is ideal for enhancing safety on large vehicles. This marking plate utilizes a micro-prismatic and aluminum construction to guarantee long-lasting visibility. Its red chevron and yellow reflective strip effectively alert other road users, ensuring safety. Furthermore, its adherence to ECE70/ECE REG 70 regulations highlights its reliability as a safety enhancer for trucks and trailers.

These reflective materials are key to enhancing road safety, offering high visibility and durability across various vehicle types and conditions.

Real-Life Applications of Reflective Materials in Road Safety

Reflective materials play a crucial role in traffic signage by ensuring road signs are visible both day and night. These materials, like EGP reflective sheeting, use micro-prisms that redirect light back to the source, such as vehicle headlights, allowing drivers to see signs from a distance. For example, many countries use reflective tape on stop signs and speed limits to enhance visibility, especially in low-light conditions. This ensures that drivers can receive important information and warnings in time to make safe decisions.

In addition to traffic signs, reflective materials are vital for emergency vehicle markings. These materials enable quick identification of emergency vehicles like ambulances, police cars, and fire trucks, even in dim light. Reflector tape enhances the visibility of these vehicles so they can be distinguished from others on the road, ensuring prompt response to emergencies. Reflective materials thus play a pivotal role in maintaining safety and efficiency in road transport systems by facilitating quick recognition and decision-making.

Future Trends in Reflective Materials for Road Safety

Reflective materials used in road safety are witnessing significant advancements, particularly through innovations in material technology. Recent developments include new coatings and the integration of smart technology to enhance visibility and durability. According to experts in the field, future trends are likely to incorporate more advanced nanotechnology, which will enable reflective materials to provide even better visibility in adverse weather conditions. Additionally, there is a growing interest in incorporating integrated sensors to produce adaptive lighting that responds to environmental changes, further boosting road safety.

Sustainability is becoming increasingly important in the production of reflective materials. Manufacturers are now exploring eco-friendly options like recyclable materials and biodegradable reflective components. This shift is part of a broader movement to reduce environmental impact and cater to the growing demand for sustainable products. The use of organic compounds and non-toxic adhesives in the manufacturing process is gaining momentum, highlighting a concerted effort within the industry to balance functionality with environmental responsibility.

EN

EN

ONLINE

ONLINE