The Science Behind Reflective Safety: How RTLITE's Products Keep You Visible

Understanding Reflective Safety and Its Importance

Reflective safety is a vital component of personal and public safety that involves the use of reflective materials to enhance visibility. These materials are specifically designed to reflect light, thereby making the wearer more visible, especially in low-light environments. The efficacy of reflective safety elements can be seen across various sectors, from clothing to safety gear, to improve the visibility of individuals and vehicles, reducing the risk of accidents.

The importance of reflective safety cannot be overstated, particularly in reducing accidents in low-light or hazardous conditions. According to traffic safety studies, the use of reflective gear can significantly decrease accident rates. For instance, statistics show that wearing reflective materials can reduce nighttime pedestrian accidents by up to 50%. This highlights their critical role not just in personal safety but also in forming a proactive approach to accident prevention. Employing reflective safety measures ensures that both pedestrians and vehicles can see and be seen, which is essential for avoiding potential hazards.

The Science Behind Reflective Materials

Reflective materials function based on the principle of retroreflection, a fascinating optical phenomenon that allows light to be redirected back to its source with minimal scattering. This property is achieved through the use of specialized surfaces, often integrating elements like glass beads or microprismatic structures. These features work by capturing incoming light and reflecting it back along a parallel path to its origin. This mechanism ensures that even in low-light conditions, reflective materials significantly enhance visibility, making them invaluable in safety applications.

There are various types of reflective materials, each designed to serve specific purposes in safety gear. Glass bead reflectors, for instance, employ small glass spheres that offer a wide-angle light reflection, commonly found in reflective clothing and traffic signs. Microprismatic materials, on the other hand, consist of tiny prism elements that provide high-intensity reflection, making them suitable for more demanding applications like construction vest striping. Vinyl reflectors are another option known for their flexibility and durability, often used in stickers and decals. These materials are critical in the production of effective and compliant safety products utilized across different industries.

Applications of Reflective Safety Products

Reflective safety products are indispensable across various industries, ensuring both worker visibility and safety. In the construction sector, workers are often exposed to low-visibility conditions, making reflective gear such as vests and hard hats a necessity for preventing accidents. Traffic management also relies heavily on reflective equipment, with traffic police and workers wearing hi-vis clothing to effectively direct vehicles and pedestrians. A report by the Global High-Visibility Clothing Market shows a steady growth in demand from 2020 to 2025, indicating the vital role of reflective safety products across different sectors. Additionally, emergency services and first responders use reflective apparel to remain visible during night operations or in adverse weather conditions.

The benefits of reflective safety products go beyond mere visibility; they significantly enhance worker safety in hazardous environments. Studies demonstrate that reflective gear reduces accidents by up to 30%, underlining its importance in occupational safety. This protective clothing not only prevents mishaps but also boosts worker confidence and focus, knowing that their safety is reinforced. Moreover, many regulations mandate the use of such products in workplaces with potential hazards, ensuring that compliance leads to safer working conditions. By incorporating these products into safety protocols, companies reinforce a culture of safety and proactive accident prevention.

Top RTLITE Reflective Safety Products

RTLITE offers a range of reflective safety products designed to enhance visibility and safety in various applications. Below are some of their top products:

The 1.24m*50m Honeycomb Self Adhesive Reflective Vinyl PVC Reflecting Sheeting is noted for its high visibility and flexibility. This product is ideal for temporary traffic signs and work zone signs due to its honeycomb pattern and waterproof nature. It also boasts a service life of up to 5 years for middle-grade performance standards.

Next, the 5.08cm*45.7m E8 104R Certificated Self Adhesive Safety Conspicuity Sticker Reflective Tape stands out thanks to its compliance with the E8 104R certification. It provides high brightness and wide angularity, making it suitable for marking vehicles and ensuring compliance with international safety standards.

The Diamond Grade Custom Caution Self Adhesive E8 104R Safety Vinyl Sticker Reflective Tape is designed for caution signage and safety warnings. This reflective tape ensures high visibility and longevity, providing effective safety solutions in various environments.

For vehicle safety, the Diamond Grade Vinyl Roll Sheeting Microprismatic Sticker Vehicle 104R Reflective Tape For Truck is a robust choice, made to improve visibility during night or low-light conditions. This tape is particularly useful for trucks, trailers, and other large vehicles.

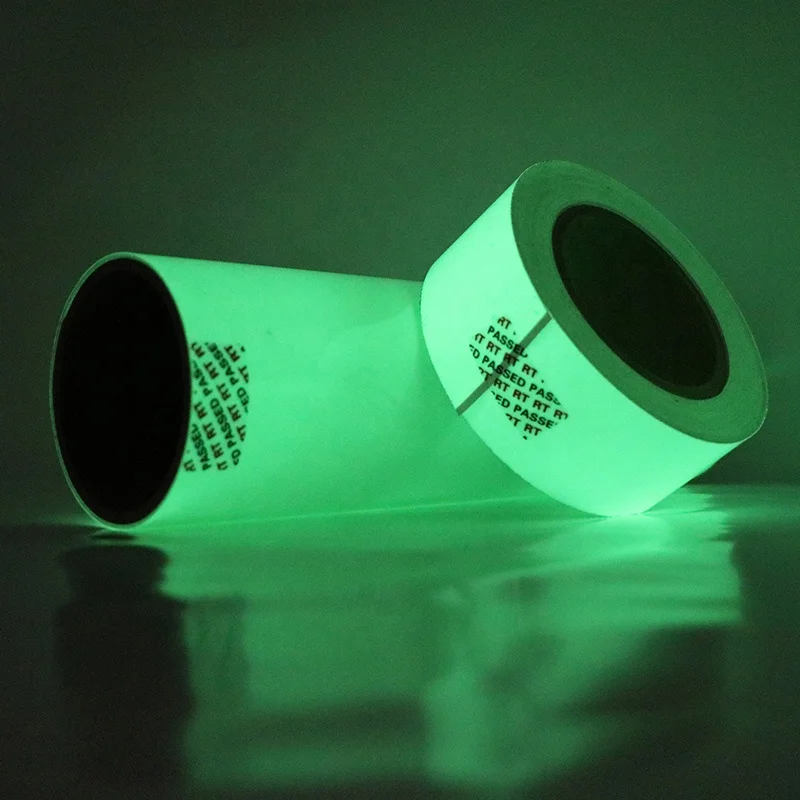

Lastly, the Photoluminescent Emergency Sign Self Adhesive PVC Green eco Solvent Printing Reflective Vinyl Glow in the Dark serves as a crucial visual aid during emergencies. Its glow-in-the-dark feature ensures that it remains visible in the event of power outages or other low-light conditions, providing clear guidance through emergency routes.

These products exemplify the commitment of RTLITE to safety, reliability, and innovation in the field of reflective materials.

Reflective Safety Standards and Regulations

Understanding ANSI Class reflectivity levels is essential for ensuring the safety of individuals in hazardous work environments. ANSI compliance involves specific criteria concerning both the amount and type of reflective material used. ANSI, or the American National Standards Institute, outlines various classes of safety gear, each with differing reflectivity requirements. For instance, Class 1 garments are designed for low-risk environments and require a minimum of 155 square inches of retro-reflective tape, while Class 3, intended for high-risk settings, demands at least 310 square inches of such tape. These standards ensure that the garments provide adequate visibility and effectiveness in reflecting light back towards its source, thus enhancing safety.

Compliance with reflective safety standards is crucial not only for ensuring worker safety but also for adhering to legal requirements. Regulations like those outlined in ANSI standards are essential as they protect workers by mandating high visibility clothing in hazardous environments, such as roadways or construction sites. Non-compliance can result in significant legal consequences, including fines and increased liability in case of accidents. Therefore, businesses must prioritize adherence to these regulations, as doing so not only safeguards their workforce but also mitigates potential legal risks.

Conclusion: Elevating Safety with Reflective Materials

The future of reflective safety products holds promising advancements that will further enhance safety standards. As technology continues to evolve, we can anticipate more innovative materials that offer increased visibility and durability. To choose the right reflective safety gear, consider factors such as the level of visibility it provides in various lighting conditions, comfort for the wearer, and compliance with current safety norms and regulations. Carefully evaluating these aspects can ensure that workers are adequately protected while performing their duties.

EN

EN

ONLINE

ONLINE